Spontaneous Sourdough Kvass

23 September 2018

Discovery of a two-week old sourdough loaf at the back of the fridge during a Sunday clearout caused a fermentation synapse to spark. Kvass! I’d never made it. I’m not sure I’d ever drunk it. But I was well aware of it, and now was the time to give it a try.

Cursory research revealed a common pattern with such things - myriad approaches, little consensus. It was already mid-Sunday afternoon, and rather than synthesise a preference I thought I’d dive in with the little learning I had. The only thing I decided as I slid into the experiment was that I’d avoid the temptation to throw dried brewers/bakers yeast at the problem.

My sourdough starter was recently put to rest for the week in the fridge, so I began by taking out a tablespoon or so and mixing it with roughly the same amounts of flour and water, making a loose paste. I set this aside, hoping it would spring back to life in time for work.

Firing up the stove I got 4 litres of water heating up. I roughly sliced the bread and laid it out in the oven which was set on grill and fan at a moderate heat. 10-15 minutes with a few turns created a well-browned pile of dry toast with a few pieces verging on charred.

Meanwhile the water had come to a boil. I turned off the heat, and immersed the toast into the the hot liquor, pushing it down to make sure it was well soaked. The effect was surprising bubbly as the crisp bread released its trapped oxygen into the water. Lid on, I left the pot to rest.

Around six hours later, the temperature was still hovering around 40 degrees. Slightly too hot to pitch. But it was getting late, and I felt I might want to add some colder water anyway to dilute things.

So I passed the bready mulch though a piece of muslin cloth into a bowl, squeezing it well, and tipped the wort into a sanitized 6 litre vessel. I was a little surprised to see only around 2 litres of fluid - I guess a lot was lost to evaporation and the absorbent bread.

I added a good glug of local honey (no measuring today) - around 1/3 of a bottle, so I’d say about 250ml. Then topped up the volume to roughly 5 litres using bottled water. A quick refractometer reading showed 5.5 Brix (roughly 1.021 SG). Temperature was a little over 30 degrees, so I pitched the now reasonably bubbly sourdough starter, careully dripping it through the neck of the fermentation vessel.

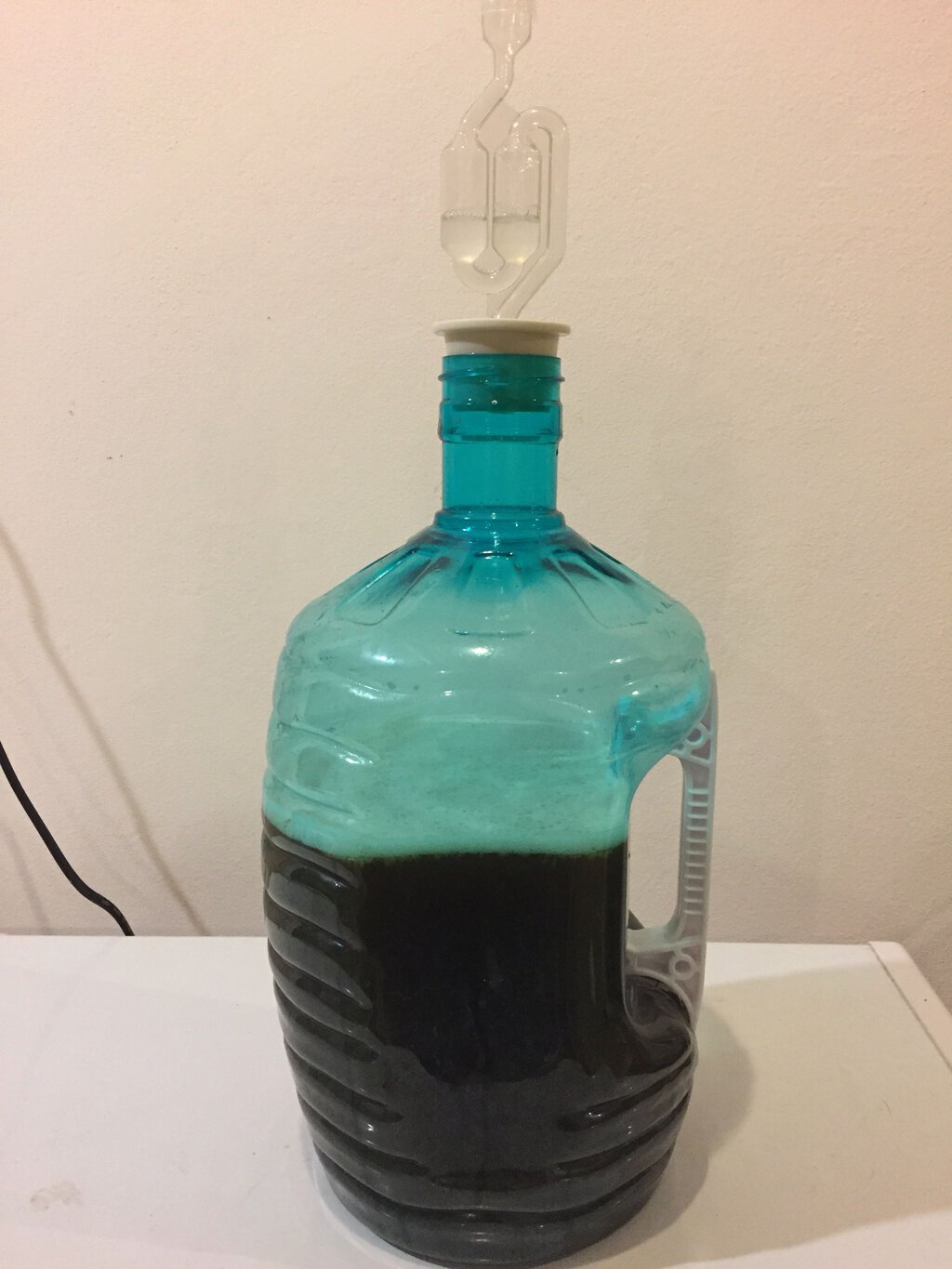

After a vigourous shake of the bottle to mix things up, I popped in a bung and airlock and left the potential to do it’s thing.

In around 24 hours, there was some evidence of fermentation on the surface of the liquid, and within 36 hours, the airlock was popping with some slow regularity. Activity built from there. While by no means vigorous, the smallish kreuzen and rising-falling motions of particles indicated reasonable yeast activity. The question was when to package this?

A little more reading suggested that it’s normal to package early, with no priming, and let fermentation continue in the bottle for carbonation. So around 72 hours after inocculation I siphoned the kvass into some flip-top containers. I also made the call to let fermenation continue at room temperature (around 25-32 Celsius) for a further period before refrigeration. At this point, specific gravity was at 1.018 - giving us around 0.4% ABV. And the flavour was quite pleasant - bready, slightly sweet, with a tiny but moreish saltiness.

That was Tuesday. In the end, I let this ferment warm until Friday, when I chilled all the bottles. By Saturday afternoon, I poppped the swing-top on one. Carbonation was only low-medium. But the flavour was quite compelling and refreshing. Notes of honey sweeteness and salt came through the now crisper, sour base, and there was a bready but in no way burnt aroma. That bottle quenched a fermenter’s thirst. It didn’t last long.

Krathon Beer - Two Month Tasting

16 September 2018

For the first time in four or five months, there was no fruit to pick up prior to mowing the lawn. This absence, this lack of interruption to the task at hand, put me in mind of that fervent brew session which finally pushed me to start these writings. As it happened, that event was exactly two months ago. While not one to succumb to fatalism, the circumstance seemed happy enough to celebrate with a tasting of one of the three remaining bottles. (Did you see that? - one, two, three, four, five…. it’s another sign.)

I selected one which had been conditioning at room temperature since bottling, and chilled it well. The pour was beautiful - radiant, blush colouring, with a full and fine head. The taste was tart and sharp, but refeshing, and the bubbles lent the draft a light, crisp mouthfeel. Something like the taste of cider with the liveliness of a sparkling wine.

I only wish there were more than two bottles left in the world. Still, there’s always next year…

No feedback yet. Share your thoughts.

Apple Cider Vinegar from Scratch

29 July 2018

Apple cider vinegar came up in a few recent conversations. As usual, my head was soon overtaken by a project to make some myself. Maybe even turn it into a regular thing.

Reading and YouTubing around turned up lots of material, much of it conflicting, on the best/correct/absolutely-only way to go from apples to ACV–some people insist that you need to add mother from a previous batch as a starter, others deny this. I finally turned to Sandor Katz’s The Art of Fermentation (where I should probably have started, in all honesty) for assurance that mother was not necessary (sorry, Mum).

The process and science is fairly simple: left to their own devices apples in water (with maybe some sugar) will ferment naturally, producing cider. If the cider is then left open to oxygen, Acetobacter will do the job of converting the alcohol to acetic acid, aka vinegar.

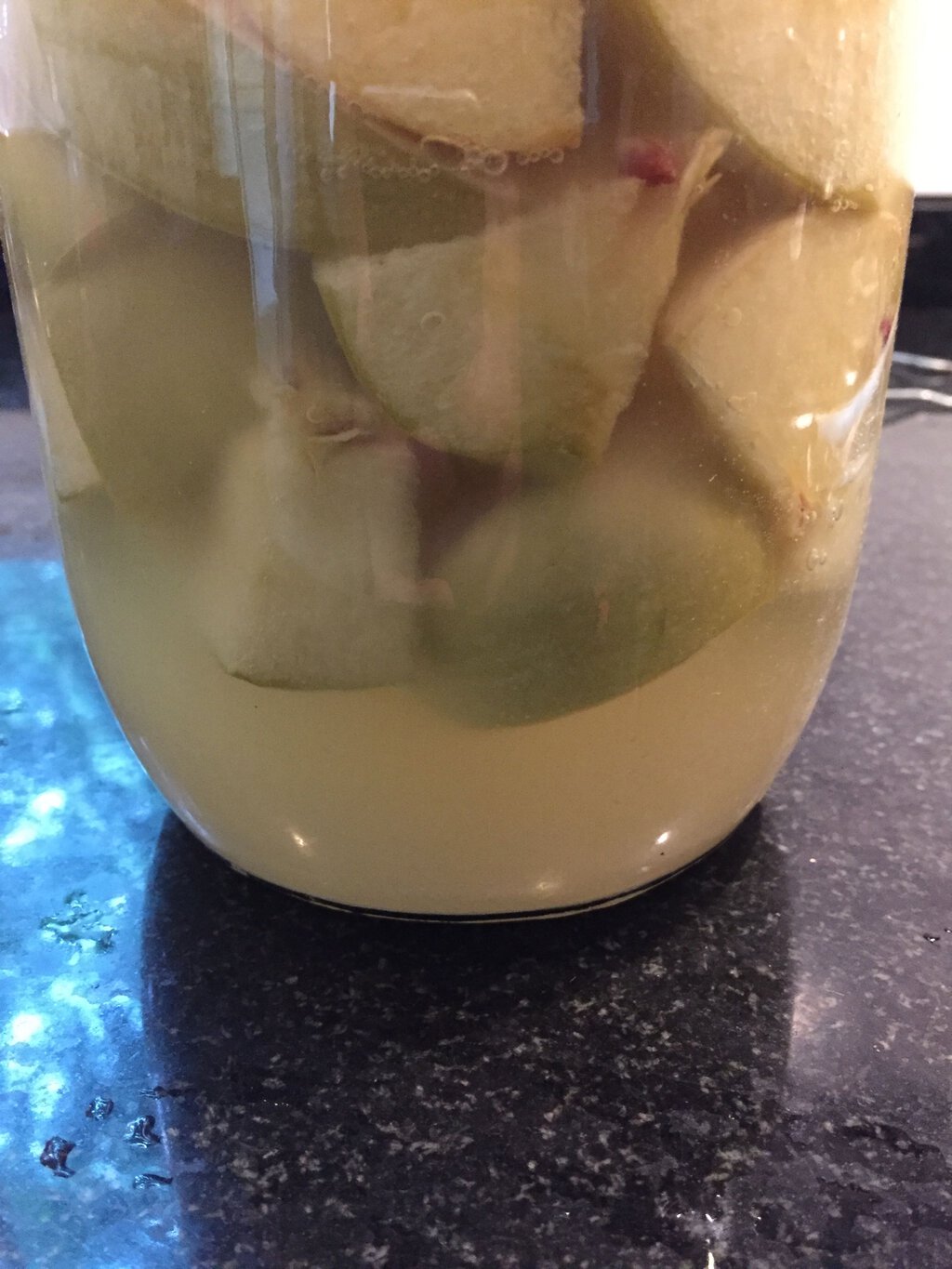

Armed with these basics, I picked up a couple of kilos of apples at the store - one each of a tarter green apple (Granny Smith) and sweeter dappled pink fruit. I roughly chopped enough of these in a 50-50 mix, preparing enough to fill my fermentation jar, leaving skins, pips and all in place. I also dissolved around 70g of sugar in 1/2 litre of water.

Minimal prep complete, I put the apples in a sanitized jar, leaving some head space and filled with the sugar solution, being careful to cover all the fruit. I placed the glass lid of another, smaller, jar atop the apples to weigh them down and keep them submerged. I then improvised a cover/hat from a coffee filter, secured with an elastic band. Practical and cute.

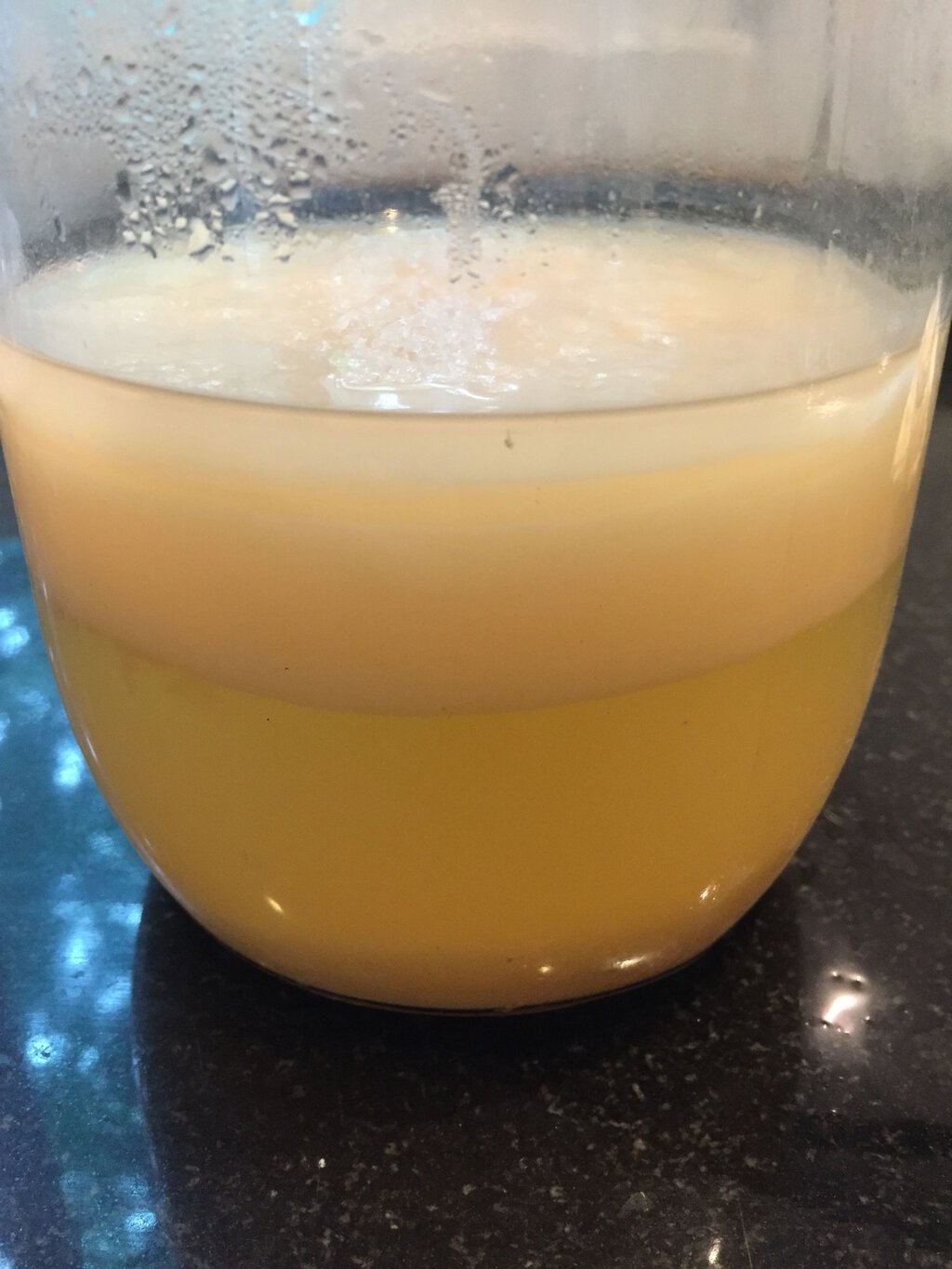

And that was it. I moved the jar to the basement, where there’s a fairly steady temperature of around 24 degrees celsius this time of year, and covered it with a black cloth. Within 24 hours, there were bubbly signs of fermentation which continued for about three days. (There were also signs of ants, no doubt attracted by that sugar, so I placed the jar in a shallow water bath to keep them at bay, until the sugar was gone).

Two weeks later, with alcoholic odours giving way to more acidic vapours, I removed the now very soft apples, straining them in a muslin cloth to extract as much liquid as possible, and returning the liquid to the same jar. I put the jar of budding vinegar back in the basement, again covered it, and let it continue on its journey for a further two weeks.

And, so, a month after chopping apples, the vinegar looked and smelled to be ready. A taste test confirmed good, sharp acidity with a lively, fruity backbone. Atop the vinegar was a gelatinous SCOBY, the missing mother, born from nothing, a good inch think. I transferred the vinegar to a sealable jar (I don’t think it will last long, so I didn’t take many precautions, beyond sanitation, for longer-term storage), and the mother along with some of her liquid progenitor to another jar. Time will tell if we let her help out with a future fermentation.

Retrospective Very pleased with the flavour of this vinegar - it is quite delicious, especially diluted with water as a drink. Keen to make more. It’s an easy process, though given the time it takes certainly worth making larger batches. I also wonder if a finer cut on the apples would allow squeezing more vinegar from the same size vessel?

No feedback yet. Share your thoughts.

No feedback yet. Share your thoughts.